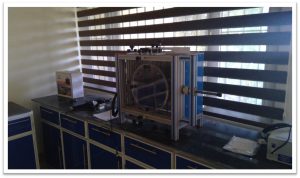

The Wind Tunnel Laboratory in the Department of Aeronautical Engineering is an essential facility used to test small aircraft models and study their behavior under simulated airflow conditions. It includes a number of specialized laboratory devices in the field of aeronautical engineering. Many experiments are conducted, and it contains models of aircraft wings specifically designed for wind tunnel studies. The wind tunnel is designed to allow for controlled and measurable airflow in the testing section. The laboratory includes advanced measurement devices for analyzing aerodynamic forces, pressure, flow, and vibrations. Students in the Department of Aeronautical Engineering use the laboratory to perform experiments and measurements to evaluate aerodynamic performance and analyze stability and structural endurance of aircraft. The laboratory provides valuable experimental data that aids in improving designs and developing new technologies in aviation. The Wind Tunnel Laboratory contributes to training students and developing their skills in aeronautical engineering, promoting progress in the aviation industry.

This laboratory serves undergraduate students across various stages by training them to use modern engineering software and general software required for aeronautical engineers. In the first stage, students learn operational systems and office software skills using Microsoft Office programs. They then learn programming principles using Visual Basic and engineering drawing using AutoCAD. In the second stage, students are trained in programming using Matlab, which is applied in aeronautical engineering applications. Students also learn structural analysis and design using well-known engineering programs such as Simulation software and other tools.

In the Department of Aeronautical Engineering, the Aircraft Structures Laboratory is a fundamental component of training students in the design, analysis, and testing of aircraft structures. The laboratory is equipped with a variety of specialized tools and equipment for conducting tensile, bending, and structural endurance tests on materials used in aircraft manufacturing. The laboratory enables students to develop their skills in using testing devices, analyzing data, and evaluating the structural performance of aircraft. It also provides a practical understanding of structural analysis, complex structure design, and testing under safety and performance standards. The laboratory enhances students’ capabilities in areas such as metallic and composite structure design, stress evaluation, and structural connection design. It plays a role in preparing students for the aviation industry and developing advanced technologies to ensure safety and high performance for aircraft.

In the Department of Aeronautical Engineering, the Fluid Laboratory focuses on studying and analyzing fluid flows in the aviation context. The laboratory is equipped with specialized devices and equipment for testing and analyzing air and fluid flows on aircraft. It allows students to gain a deep understanding of the aerodynamic and fluid streams surrounding aerial objects and their impact on performance and resistance. The laboratory also facilitates the study of complex interactions between objects and the surrounding streams. It employs measurement techniques and computer software to analyze data, design, and optimize fluid flow engineering. The laboratory provides a dynamic environment for practical learning and experimentation in aeronautical engineering and its applications in aircraft design and aerodynamic performance.

This specialized facility focuses on studying and analyzing jet propulsion systems in aircraft. The laboratory is equipped with a variety of jet engines and related components for conducting experiments and tests. It allows students to gain deeper insights into jet propulsion principles and their impact on aircraft performance and stability. The laboratory also provides opportunities for designing and analyzing jet propulsion systems, evaluating their efficiency, and fuel consumption. It uses advanced measurement devices and computational tools to analyze data and simulate jet propulsion behavior under various conditions. The laboratory serves as a critical site for developing modern technologies in jet propulsion and improving engine and system efficiency. It contributes to student training and skill development in designing and analyzing jet propulsion systems and advancing the aviation industry.

This vital facility aims to develop and test virtual models of aircraft. The laboratory is equipped with advanced computer systems and simulation software for designing and analyzing aircraft performance. It provides a virtual environment for students to develop their skills in aircraft design and analyze factors affecting their performance, such as aerodynamics, stability, and control. The laboratory also allows students to experiment with different scenarios and changing flight conditions through virtual simulations. It uses digital simulation technologies and 3D modeling to visualize and analyze aircraft behavior under various conditions. The laboratory offers a dynamic educational environment for students to enhance their understanding of aircraft design and analysis and learn to use advanced tools and software in the field.